In August 1989, I (Chris Wood), traveled to NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, California for a historic event.

I was only 10 years old, so I took my dad along for the ride. As a former aerospace engineer for Grumman (now Northrop Grumman) who worked on a bunch of NASA projects, including space shuttle design and mission analysis, I figured he’d fit in just fine.

We were there to see the first-ever close-up images of Neptune that NASA’s Voyager 2 spacecraft would beam to Earth from nearly 3 billion miles away as it flew by.

Even though I was just a kid, I distinctly remember thinking how cool it was when I saw the first real-time images of the blue ice giant appear on the screens at JPL.

The experience affected me as much as seeing Halley’s Comet a few years earlier and my first total solar eclipse a couple years later. And it was all thanks to Voyager 2 and the folks who made its mission possible.

Voyager 2 continues to race away from us at about 35,000 mph. It’s now in interstellar space about 13 billion miles from earth.

As Chris Reilly explained here, Elon Musk’s SpaceX singlehandedly revived the final frontier.

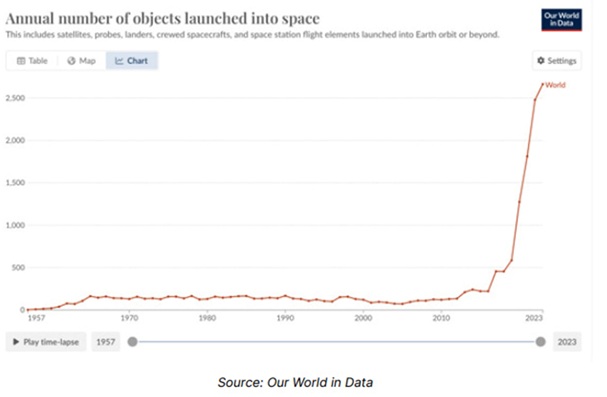

Look at this chart showing the number of objects launched into space:

Thanks to SpaceX, more objects reached orbit in the past two years than in all of previous history. SpaceX accounts for 95%+ of these launches. Imagine if every time you flew, the airline had to build a new plane. That’s how space travel used to work. Every rocket flew once, then crashed into the ocean.

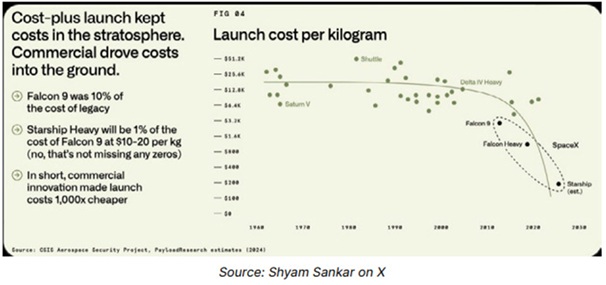

SpaceX changed the game by building reusable rockets that land themselves after launch, ready for the next trip. In 2000, putting a pound of cargo into orbit cost at least $30,000. Today, SpaceX routinely does it for $1,200—cheaper than a new iPhone Pro. That’s a 96% cost reduction!

By slashing the cost of reaching orbit, SpaceX is making the new space economy possible.

Imagine a giant floating laboratory, bigger than a football field, zooming around Earth every 90 minutes. That’s the International Space Station. It has flourished into a bustling factory for groundbreaking medical research that can’t be conducted on Earth.

In September 2023, scientists aboard the ISS successfully 3D printed the first human knee meniscus in orbit. Redwire (RDW), which owns the Bio Fabrication lab on the ISS, then sent the meniscus back to Earth aboard a SpaceX rocket.

Eight months later, Redwire announced the successful 3D bioprinting of live human heart tissue aboard the ISS. Why do this in space? In a word, microgravity. On Earth, gravity pulls down on soft biomaterials, causing them to collapse or lose structural integrity before they solidify into the intended shape. Picture a failed soufflé. No problem in space, where everything is near-weightless.

Microgravity is a game-changer for drug discovery and development, too. For example, the process of crystallizing a protein to analyze its 3D structure allows scientists to understand how potential drugs might interact with that protein to treat disease.

I should also note that most drugs target proteins because most diseases can be traced to the underproduction of a protein, the overproduction of a protein, the mutated version of a protein, or some combination thereof. Here on Earth, gravity affects how molecules interact and form crystals. This makes it challenging to get clear pictures of protein structures.

In microgravity aboard the ISS, molecules can interact more freely, allowing proteins to form more perfect crystals. This gives scientists clearer pictures of their structure. Think of developing a drug like creating a key for a specific lock (the protein target).

The better you can see the lock’s shape, the easier it is to design the perfect key. The high-quality protein crystals grown in space provide much more detailed images of these molecular “locks,” helping scientists design more effective drugs.

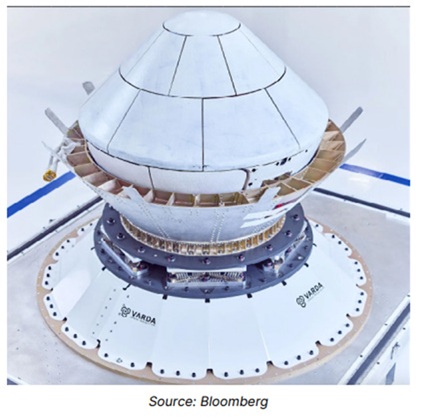

Progress is happening here fast. Los Angeles-based startup Varda (a private company) recently launched the world’s first space-based drug factory. Varda’s capsule hitched a ride on a SpaceX rocket, made some pills in orbit, and then parachuted back to Earth. The next lifesaving drugs could be made inside this 3 ft. wide capsule, 400 miles above our heads. What a time to be alive!

Don’t underestimate the impact of cost reduction. It’s often how new industries are born. Varda, for example, was never a viable business because it would’ve cost $20 million+ to send its 660 lb. mini drug factory into orbit 20 years ago.

SpaceX delivered it into space for less than $2 million. Imagine all the Vardas that will be built because we can now get to space for less. The iPhone gave us Uber (UBER), Netflix (NFLX), and Meta (META)...

What trillion-dollar ideas will cheap space travel spawn? One day, we’ll look back and laugh that humans had to make everything on Earth. The final frontier is (finally) open for business—and investment opportunities abound.

If you liked this, consider joining our new Grow or Die Substack, where we write about how to invest in growth stocks the right way. Free insights Monday-Friday, including Case Studies, Peter Lynch principles for the modern markets, and much more. Go here.

-Chris Wood